We fabricate Granules/Powders by Spray Drying

| The spherical and flowable powders produced by spray drying can be used in pressing-sintering, plasma spray coating, and 3d printing methods. |

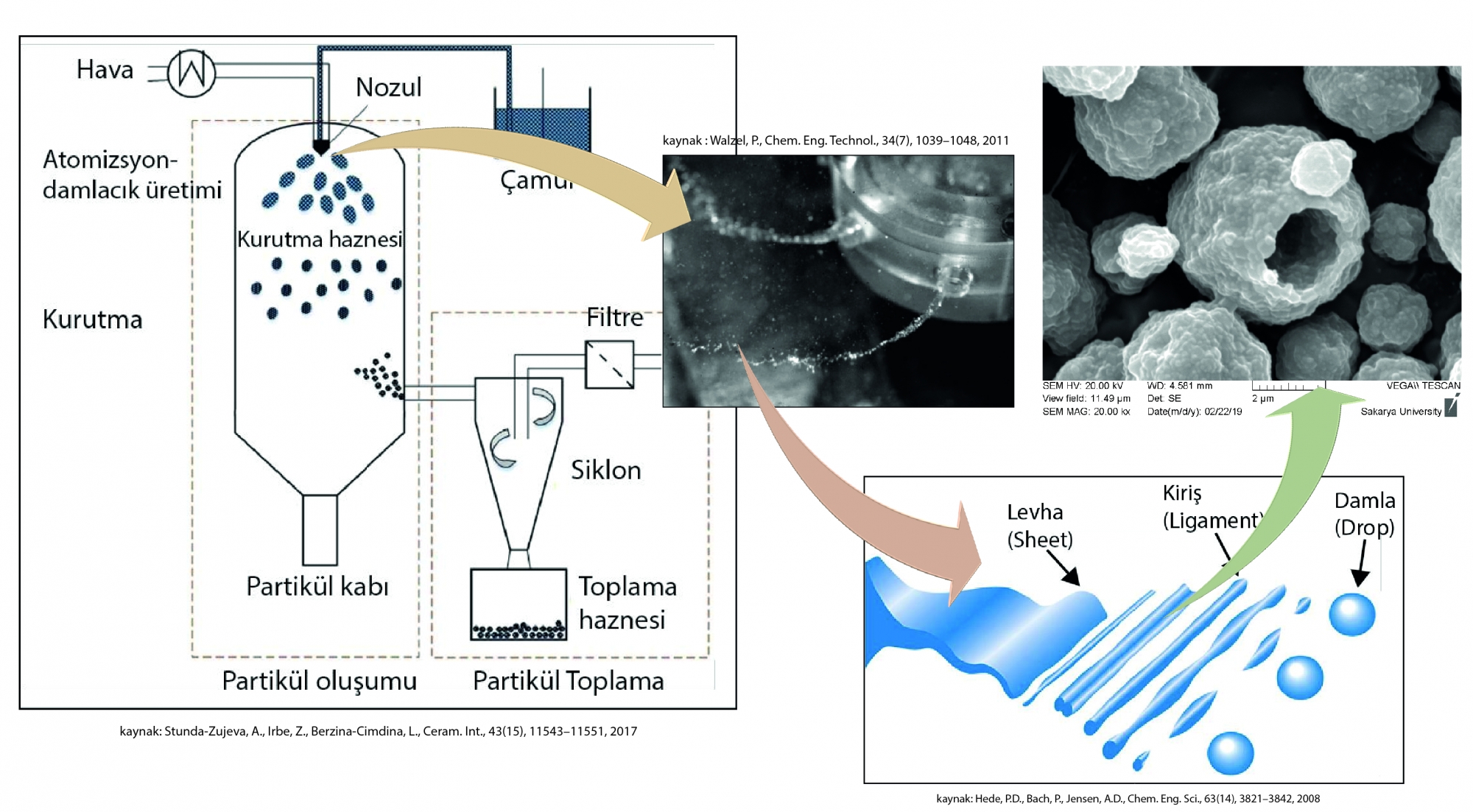

Schematic representation of process stages of powders/granules' fabrication by spray drying. In the spray drying process, a slurry prepared from the fine particles is fed into an atomizer mounted in the drying tower. The pressure applied on the atomizer breaks the slurry into droplets, which are then dried by the heated air. By adjusting parameters, particles with diverse shapes and sizes can be prepared.

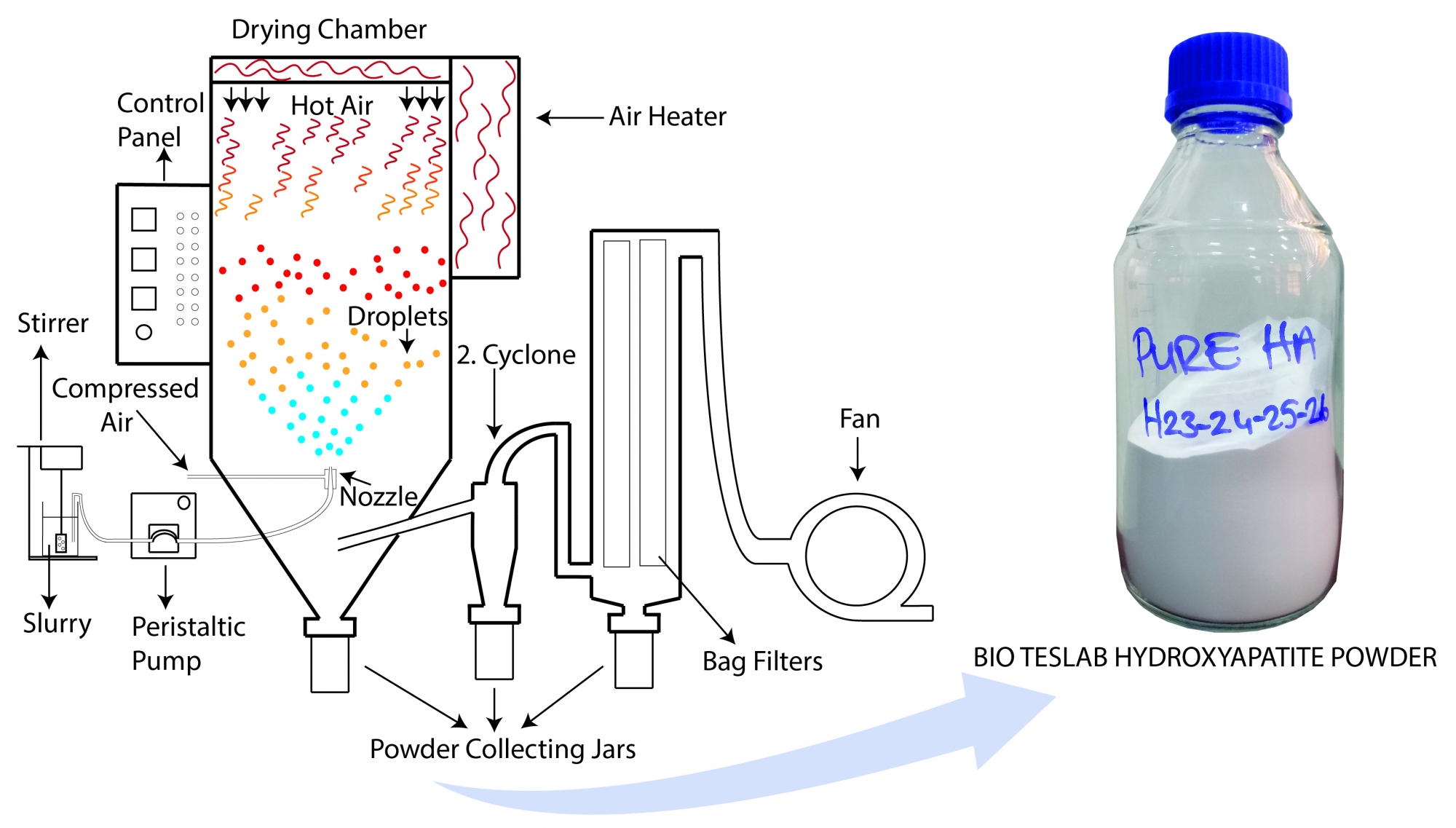

Schematic of our spray drying system. Flowable BIO-TESLAB hydroxyapatite granules produced in this equipment

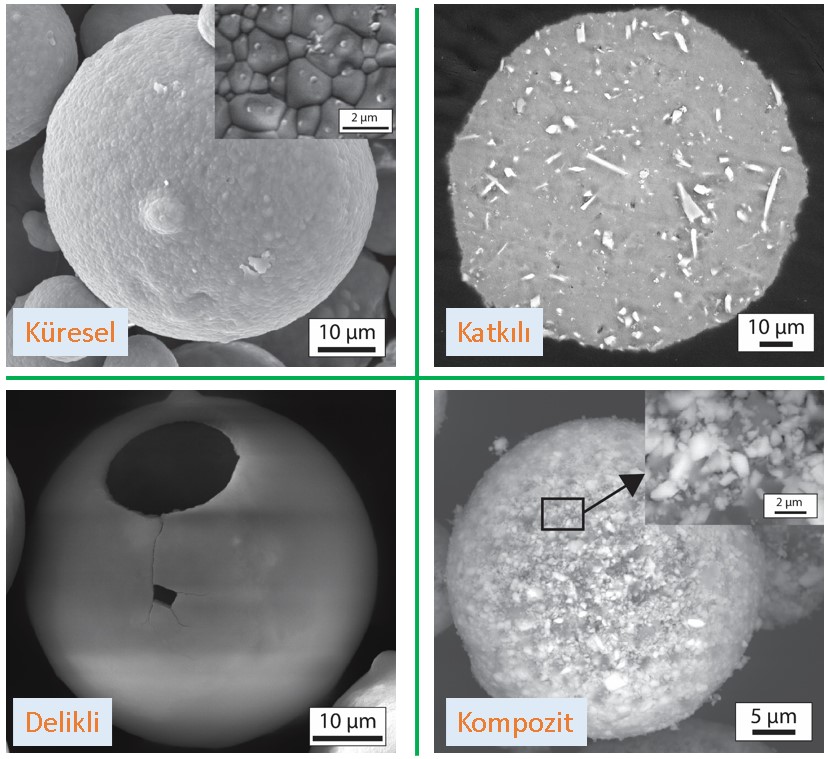

| The BIO-TESLAB team has ten years of hands-on experience in suspension/slurry preparation and spray drying procedures. Here, the granules have different particle shapes produced by spray drying. Granules with specified and narrow size distributions and spherical, hollow, and donut shapes can be fabricated. |

Scanning microscope images of prepared powders/granules by spray drying in our laboratory. Spherical (küresel), reinforced (katkılı), hollow (delikli), composite (kompozit) shapes.