We fabricate biomedical coatings by plasma spraying

| In this thermal spraying procedure, the powders fed into a high-temperature plasma are accelerated and sprayed on a substrate. The adhesion strength of the coatings is relatively high, and they do not require any post-sintering procedure also. Hydroxyapatite-coated implants promote the integration between bone tissue and orthopedic implant, enabling bone ingrowth and supporting structural adhesion between host tissue and implant. Hydroxyapatite coatings are used in arthroplasty implants, trauma components, dental and spine implants.

Schematic illustration of plasma spraying gun and produced coatings by plasma spraying |

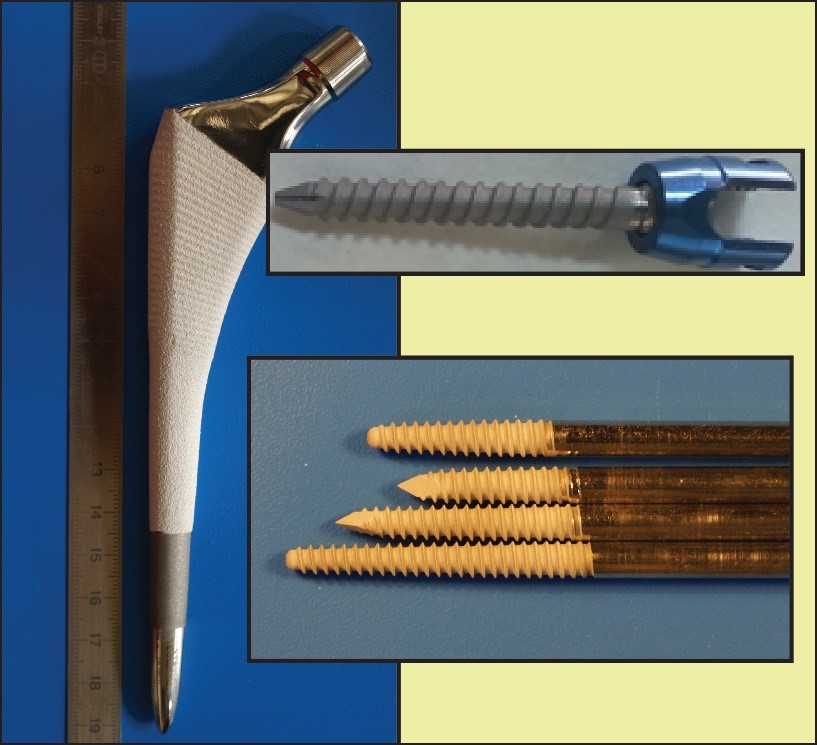

| These are examples of some Hydroxyapatite deposited implants used in surgical applications. (hip-joint implant, Schanz screw, polyaxial screw). HA-coated implants establish a structural integration with host tissues The advantages of plasma sprayed HA coatings: Controlling the phase structure, adjusting the microstructure and thickness, elevated adhesion strength, high production rate, cost efficiency, high surgical successful rate |

|

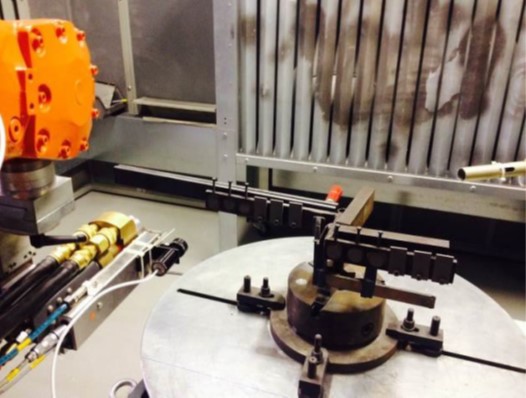

The process photos of the deposition of the Schanz screw: The coatings are produced in a specific cabinet. The sand-blasting, coating, characterization, and packaging procedures are operated in BIO-TESLAB. |

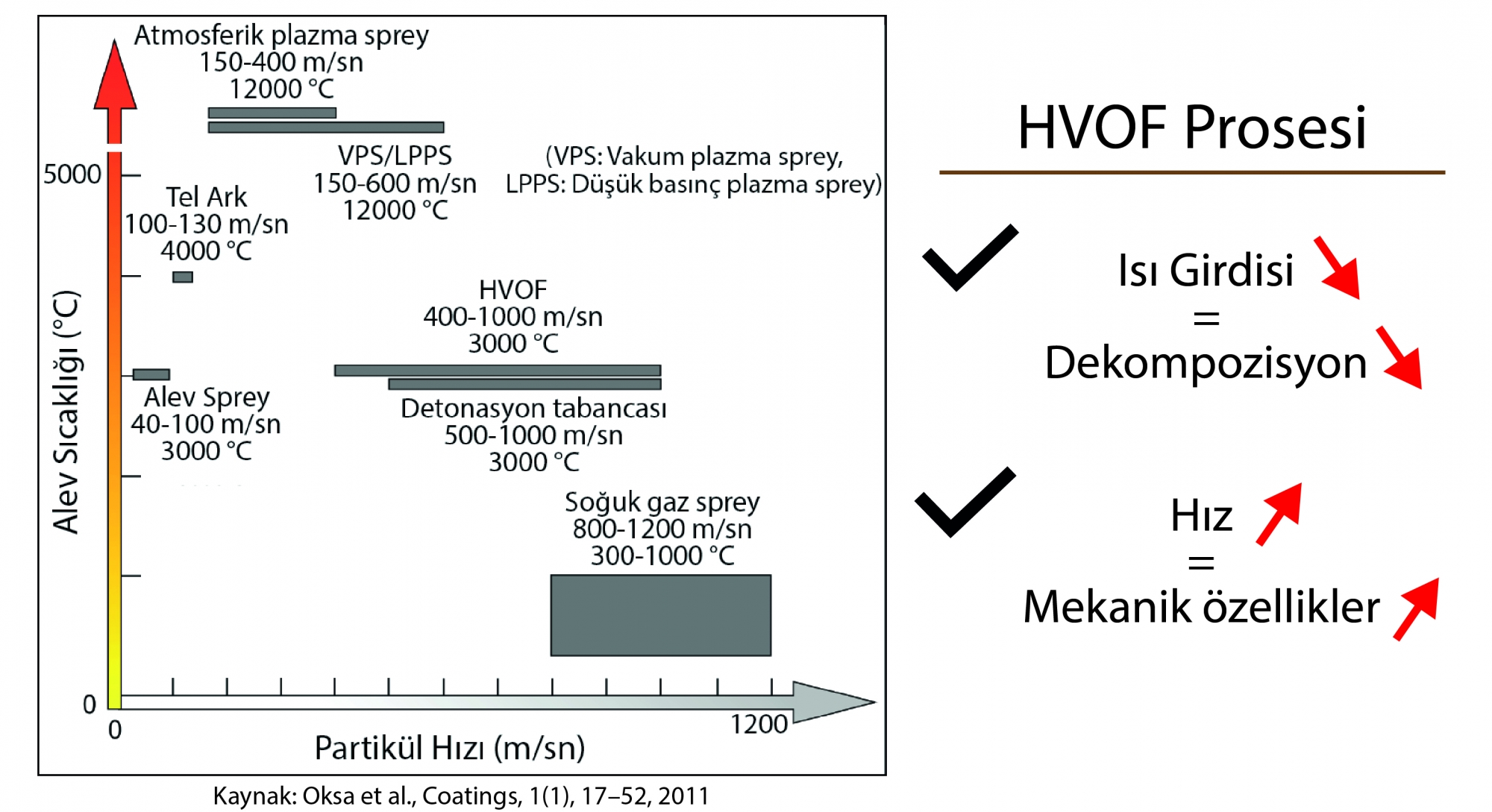

Besides, we use HVOF system for biomedical coatings

| As distinct from other thermal spraying applications, particles are heated to moderate temperatures and accelerated up to 1000 m/sec in the HVOF method. |

| We produced HVOF hydroxyapatite coatings with the granules (d50: 5-10 microns) engineered in our laboratory by spray drying. |

|

The SEM images of HVOF deposited hydroxyapatite coatings fabricated in our lab, having 150 microns thickness and dominantly hydroxyapatite phase structure. |